Amazon is testing Agility Robotics’ humanoid robot, called Digit, in its warehouses. Agility Robotics says Digit can quickly adapt to existing warehouse floorplans. But the human form may not be the most ideal shape for warehouse tasks, Boston Dynamics’ CTO said

According to Boston Dynamics’ CTO, the human form may not be the most ideal shape for warehouse tasks. However, humanoid robots have “great potential” in closing the “technology gap” and will be crucial in the field of “general-purpose robotics”.

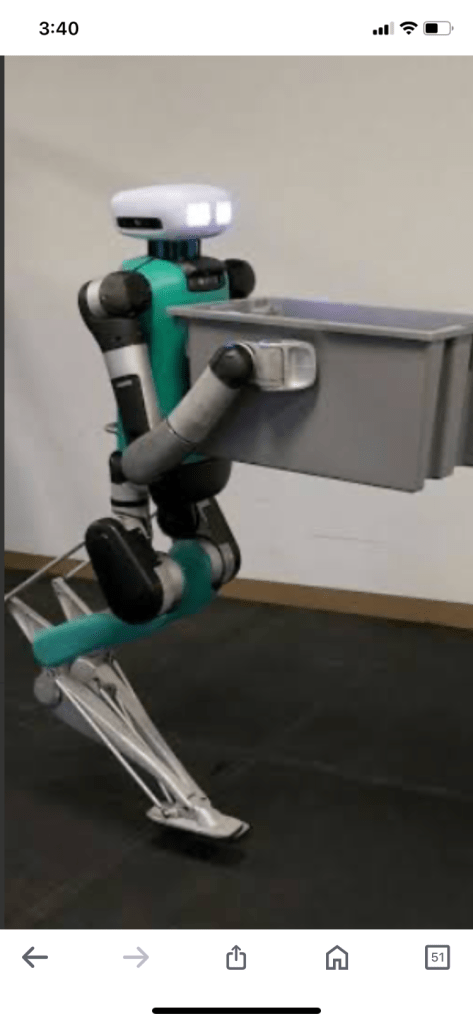

Amazon is testing Agility Robotics’ humanoid robot, called Digit, in its warehouses. Digit has a head containing cameras, other sensors and animated eyes, and a torso that essentially works as its engine. Digit can quickly adapt to existing warehouse floorplans.

Other humanoid robots that can lift boxes in warehouses include:

- Boston Dynamics’ Stretch

- Tesla’s Optimus

Robots in Amazon’s warehouses can have many benefits, including:

- Efficiency: Robots can work around the clock without breaks, and can move goods faster than humans.

- Cost reduction: Robots can reduce labor costs and operating costs.

- Sustainability: Robots can ensure efficient use of energy.

- Order accuracy: Robots can increase order accuracy.

- Productivity: Robots can increase productivity.

- Employee experience: Robots can improve the employee experience.

- Injuries: Robots can reduce the likelihood of serious injuries.

Other benefits of robotic technology in warehouses include:

- Better warehouse optimization

- Better inventory management

- Improved customer satisfaction

- Reduced errors

- Faster order fulfillment

- Optimum picking rates

Some challenges of using robots in Amazon warehouses include:

- Wrongful terminations: Automated systems don’t always work, which can lead to wrongful terminations.

- Insufficient medical support: There may not be enough support for medical issues.

- Higher injury rate: A 2019 report found that Amazon’s robotic fulfillment centers had a higher injury rate than its older facilities

Amazon says that its robots are designed to work alongside employees, not replace them. Amazon has over 750,000 robots that work with employees to take on repetitive tasks. The goal is to reduce physical tasks for employees so they can be more focused and efficient. Amazon also offers a 12-week upskilling program and employment opportunities in over 700 new categories.

However, some say that Amazon may be planning to replace human workers with humanoid robots. Automated fulfillment solutions are a compelling next step for retailers

Amazon has reiterated that its robotic systems have helped generate “hundreds of thousands of new jobs,” including over 700 new job categories requiring “skilled roles.” While Amazon utilizes over 750,000 robotic systems, they are said to work “alongside” humans, rather than “instead” of them

Amazon says that robots can improve safety in its warehouses. In 2022, Amazon reported that recordable incident rates were 15% lower and lost-time incident rates were 18% lower at robotic sites than at non-robotic sites

Some hazards associated with human interaction with robots include:

Human errors, Control errors, Unauthorized access, Mechanical failures, Environmental sources, Power systems, Improper installation.

Some protections for industrial robots include:

- Guardrails

- Chain link fencing

- Walls

- Light curtains

- Electric safety mats

- Warning signs

- Floor tape

Amazon has also introduced a new robotics system called Sequoia to improve safety. Sequoia uses robotic arms and computer vision to identify inventory and transport it to employees.

Proteus robots were conceived as inherently collaborative (i.e., safe to be around workers) and thus are equipped with “advanced safety, perception and navigation technology” that Amazon engineered at no small expense. Just last year, Amazon set up a $1 billion innovation fund to spur logistics innovation

Introducing Titan, Amazon’s new mobile robot that can lift up to 2,500 pounds. Titan expands on the history of Amazon’s robotics innovations, helping move heavy and bulky items in our fulfillment centers. Amazon is deploying a new robot to take on the extra-heavy lifting in its fulfillment centers

Amazon is testing the humanoid robot Digit in its warehouses. Digit is a bipedal robot that can pick up objects, squat, bend, and grasp items. Amazon is using Digit to consolidate totes, which involves organizing and repositioning storage containers after all the inventory has been removed. Digit can sense, grasp, and move bulk objects autonomously

Digit was developed by Agility Robotics, a company that Amazon supports. Amazon has primarily focused on wheeled autonomous mobile robots (AMRs), but their interest in Digit shows their curiosity about walking robots and their potential.

Digit’s size and shape are well suited for buildings that are designed for humans. Amazon aims to optimize efficiency by introducing these robots.

One of Agility Robotics’ selling points for Digit is the robot’s ability to adapt to existing warehouse infrastructure and floorplans that weren’t necessarily designed for robots and automation. According to the company, it can also lift objects of various sizes and weights(full article source google)

Best telescopes on heavy discount on Amazon