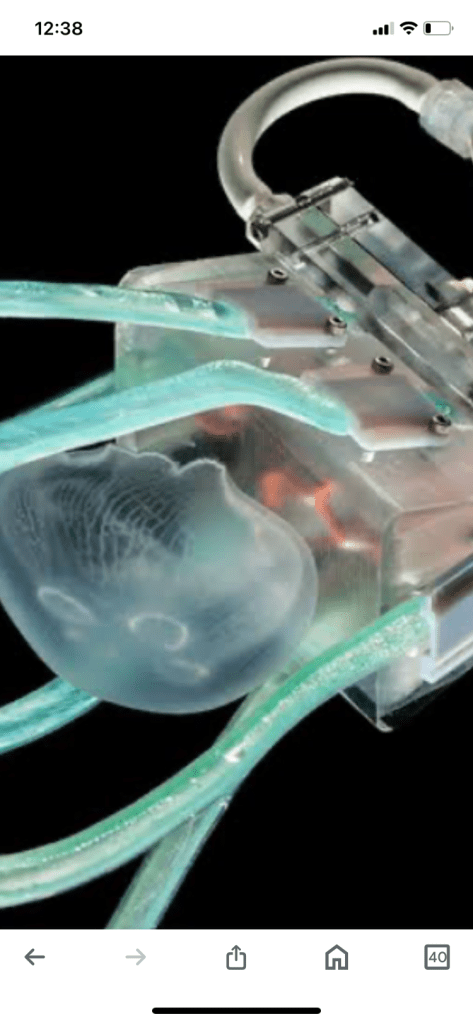

A self-healing robotic gripper has been developed for use in soft robotics. It is adaptable, recyclable, and resilient to damage. The gripper has a flexible and deformable membrane made from a self-healing elastomer.

Soft grippers are suitable for delicate tasks. They have four legs that inflate to gently pick up objects.

Robotic grippers are used in manufacturing to pick, hold, and move products. They are faster than human hands and provide a higher output.

There are four types of robotic grippers:

- Vacuum grippers

- Pneumatic grippers

- Hydraulic grippers

- Servo-electric grippers

Some other types of grippers include:

- Grippers with two and three fingers

- Claw-shaped grippers

- Mechanical grippers

- Grippers with large suction cups

- Grippers that look like air-filled bags

The Gripper mold is made of traditional cardboard, laminated with clear packing tape and assembled with hot glue to seal the corners and to ensure there is no leakage when molding. The molding process is conducted in two parts. The first layer is cast with silicone to the first line halfway up the cardboard mold

A robotic gripper is a mechanical or robotic device that grasps, holds, manipulates, or transports objects. It’s the “hand” of a robotic arm or automation system, allowing the robot to interact with the physical world.

There are four types of robotic grippers:

- Vacuum grippers Use the difference between atmospheric pressure and a vacuum to lift, hold, and move objects. They’re used for a wide range of products, but are most commonly seen handling objects that are smooth, flat, and solid.

- Pneumatic grippers Also known as air-activated mechanical grippers, they’re a popular type for accurately handling individual parts in a manufacturing process. They use compressed air and pistons to work accurately and hold on to products.

- Magnetic grippers Designed to work with ferromagnetic workpieces where gripping may not be ideal. They work well in applications where space is a premium.

- Servo-electric grippers Manufacturers choose grippers based on which handling application is required and the type of material in use.

Robot grippers can be made from a variety of materials, including:

- Silicon rubber: Used to make soft grippers that can grasp soft materials

- Aluminum alloy: Used for gripper components

- Fine dust material: Used for universal grippers

Other types of grippers include:

- Parallel-finger grippers: Designed for working in tight spaces

- Universal grippers: Used for gripping and discharging large numbers of objects

- Needle grippers: Use needles to provide both friction and mechanical grasping

Soft robotic grippers are flexible and adaptable to new environments. They can handle a variety of objects with different shapes, textures, and consistencies. Soft grippers are ideal for delicate tasks because they can conform to the shape of the object and distribute grasping forces. They can also make human-robot interaction safer

Soft grippers have been used in many applications, including:

- Soft grippers

- Locomotion robots

- Medical devices

- Human-machine interfaces

Soft grippers can be made from:

- Magnetic actuators: These consist of a magnet embedded in a flexible, elastomeric material.

- Four inflated legs: These can gently pick up objects.

- Integrated polymer actuators: These use electroadhesion and electrostatic actuation to grasp objects.(full article source google)

Best desktops on heavy discount on Amazon

https://19b9dnhp62u-irkj5jcy-8dhft.hop.clickbank.net

This is so interesting.

LikeLike