US scientists have demonstrated a groundbreaking innovation in animal experiments: Using ultrasound, they have succeeded in three-dimensionally “printing” biomaterials directly inside organs. This could enable minimal interventions without surgery

Researchers have used ultrasound to 3D print objects remotely, even through walls. This new form of 3D printing uses sound waves to move matter without touching it. The deep penetration of ultrasound waves allows for printing through tissues that are too thick for light-based printing techniques.

This new 3D printing process could be used for:

- Bone healing

- Heart valve repair

- Minimal interventions without surgery

The hope is that this will lead to safer and less invasive surgical procedures.

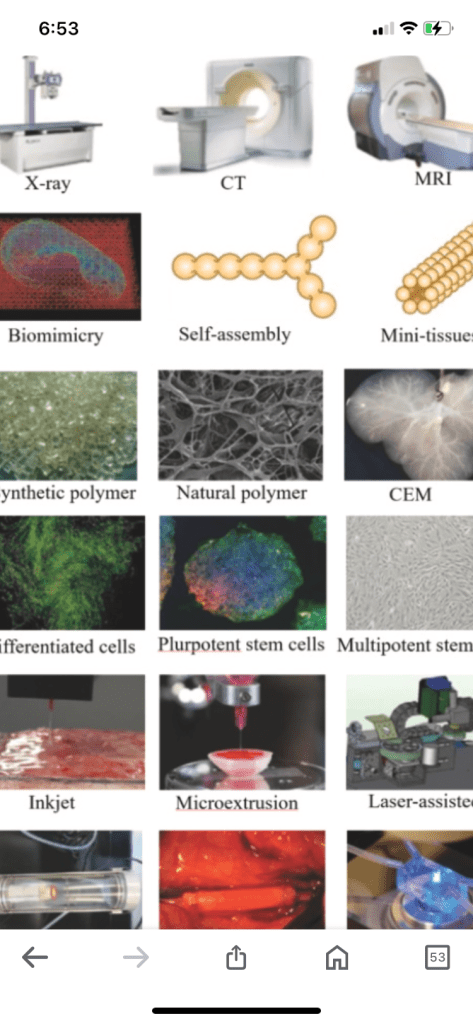

3D printing has many applications in biomedical engineering, including:

- Organ models: 3D printing can create patient-specific replicas of bones, organs, and blood vessels. These models can be used for patient education and surgical planning.

- Prosthetics and implants: 3D printing can create personalized prosthetics and implants.

- Surgical guides: 3D printing can create surgical cutting and drill guides.

- Bioprinting: 3D bioprinting uses bioinks mixed with living cells to create tissue-like structures. This technology can be used for tissue engineering and drug development.

3D printing can also help medical device companies develop better products faster.

3D printing, also known as additive manufacturing, is used to create physical replicas of anatomical structures for medical devices. 3D printing is used in both clinical and research-based healthcare activities.

Some examples of 3D printed medical devices include:

- Surgical tools: Forceps, retractors, medical clamps, needle drivers, hemostats, and scalpel handles

- Implants: Cranial and maxillofacial implants, bone grafts, orthopedic and cranial implants, and drug delivery implants

- Prosthetics: External prosthetics and patient-specific prosthetics

- Anatomical models: Patient-matched anatomical models and surgical guides

- Drug delivery devices: Personalized size and shape devices for local and systemic delivery of API through the intrauterine route

3D printing offers several advantages over traditional manufacturing technologies. For example, patient-specific implants can reduce costs associated with postoperative infections.

3D printing has many applications outside of medicine. Some of these include:

- Manufacturing

- Architecture

- Custom art and design

- Food manufacturing

3D printing can also be used to create:

- Prototypes

- Jigs and fixtures

- Customized medication dosages and formulations

The global market for 3D printing in medical applications was valued at $2.8 billion in 2022. It’s expected to grow to $11 billion by 2032.

Some potential disadvantages of 3D printing in medicine include:

- Cost: 3D printers and materials can be expensive.

- Precision: 3D printed tools can be more precise than traditional tools.

3D printing in medicine has some limitations, including:

- Cost: 3D printers and materials can be expensive.

- Raw materials: Some materials, like plastics, need to be ground into small particles for the printer.

- Safety and efficacy: There are no long-term studies on the safety and efficacy of 3D printing.

- Functionality: 3D printers are limited in functionality compared to some traditional manufacturing methods.

- Cyber risk: 3D printers can be used to produce counterfeit medicines.

- Inflexibility: 3D-printed models are typically inflexible, which makes application difficult in cases involving soft tissue.

Other limitations of 3D printing include:

Limited materials, Restricted build size, Post processing, Large volumes, Part structure, Design inaccuracies, Copyright issues. (Full article source google)

Best telescopes on heavy discount on Amazon

https://130ealik57-6kr9kngv7ujukpe.hop.clickbank.net